ADJUSTING A VIOLIN (Checklist)

EXAMINE the violin overall.

Note what needs to be REPLACED, or is missing. For example, we may decide to replace the original equipment strings with Helicore, the fine tuners with a Wittner Tailpiece, and the tailgut with a "Sacconi." If the bridge is a poorly cut, mushy one, we will choose and fit a hard one, a genuine Aubert or similar. Collect the materials needed.

REMOVE the strings, bridge, tailpiece, chinrest, endpin, and soundpost. Leave the pegs in for now to avoid interchanging them.

NOTE: The order of the next three steps may have to be altered. For example, a nut may have to be removed so a fingerboard can be properly planed.

Check the FINGERBOARD for the curvature and lengthwise concavity ("scoop") and correct it if necessary. This is often overlooked on student violins and causes no end of buzzes and botheration. A straight board is nearly tolerable, especially in the lower positions, but one that droops toward the bridge is not. Such a warp may occur when an instrument is shipped with the strings down tight against (instead of alongside) the fingerboard, or is packed too tightly. Also lift up on the lower end of the fingerboard to check if it is loose. This hidden problem is a frequent cause of neck warping.

Check the fingerboard PROJECTION at the bridge line (between the inner soundhole notches), about 27 mm high on a normal 4/4 violin. If it is too low you may decide to "reset" it by loosening the upper half of the front, placing a shim between the base of the neck and the front, and regluing. (In more extreme cases, reject the violin - it was made wrong.)

Check and correct the string NUT as necessary. They are generally too high on new factory fiddles, making them hard to play. File the nut down to about a mm above the fingerboard, and sloping down into the pegbox. Recut the grooves as needed about 5.5 mm string center to center, but all the grooves should be shifted about a mm toward the bass side. See the template in 'Useful Measurements," page 12. The string grooves at the nut (and at the bridge) should be about as wide as the string diameter, but only about 1/3 as deep. Use a "mouse tail" file. The string should rest "on," not "in" the grooves. Remove any sharp edges from the ends of the nut with a flat file, rounding them smoothly down to the fingerboard and pegbox. (On old violins the strings may be too low at the nut, causing buzzing. Make a new nut or place a shim under the old one so there is at least a quarter mm under the E string and a third of the string diameter under the others.)

Make sure the PEGS fit and operate smoothly and securely after applying Hills' peg compound. Pegs on new violins often fit poorly, are too long, are out of round from shrinking, have ugly sawn ends, have too small or wrongly placed string holes, etc. See "Violin Making, Step by Step," pages 62-64 for details of peg fitting.

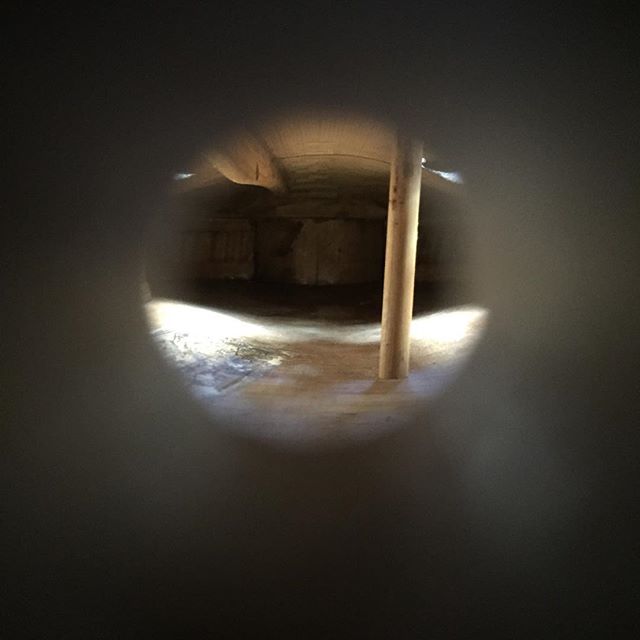

Check the POST for correct grain direction, angle and fit of the front and back ends, and length. A too tight (too long) post can cause disastrous cracks as well as a cramped tone. See "Useful Measurements," page 23 for its position and adjustment. Reset it through the treble soundhole, then looking through the endpin hole to check that it is vertical. Also note: a good rule is that the post should be about as far from the bridge as the front is thick. This helps keep thin violins from tubbiness and thick ones from brassiness.

Install the FINE TUNERS into the tailpiece, insuring adequate clearance for ball end strings and checking that they operate smoothly. (A little beeswax is a great help.) Reinstall the endpin. Install the tailgut into the tailpiece, adjusting the knurled brass nuts so that, when under string tension, the lower end of the tailpiece is even with the lower edge of the saddle. Usually this will give about the right distance from the bridge to the tailpiece. Cut off excess tailgut length.

Fit the feet of the BRIDGE precisely to the front of the violin and at the right "backtip" angle. See the diagram in "Useful Measurements," page 22, and "Violin Making, Step by Step," pages 66-70 for details of bridge fitting. (You really need this book, or a good teacher, if you're new at cutting bridges.) The bridge height is set with the G and E strings temporarily installed. The upper edge, its curvature, thickness, and grooves are then completed.

Apply a little GRAPHITE lubricant from a No. 2 pencil to the nut and bridge string grooves.

Now install the STRINGS in the "upward pegbox" order, G, E, D, A. The strings are wound so as to end just snugly at the side of the pegbox, not jammed against it. This enables smooth, secure tuning, without danger of the peg coming completely loose. High quality modern compound steel core strings give excellent sound, are more stable and durable than the gut or synthetics, and are a better match to the convenience of fine tuners.

Select and install a suitable CHINREST. Many teachers do not recommend the flat "Guarneri" style for young students, however usual among performers. An "edu" or "low Teka" gives better security and comfort. Avoid the waffle-grid types. For those few students whose chin straddles the tailpiece, a "Flesch model without the hump" is recommended. SHOULDER REST selection is best left to the player or teacher, but don't stock any that damage the instrument.

Play it and adjust the bridge position and angle, post, etc. and don't put it on the shelf until it's right!